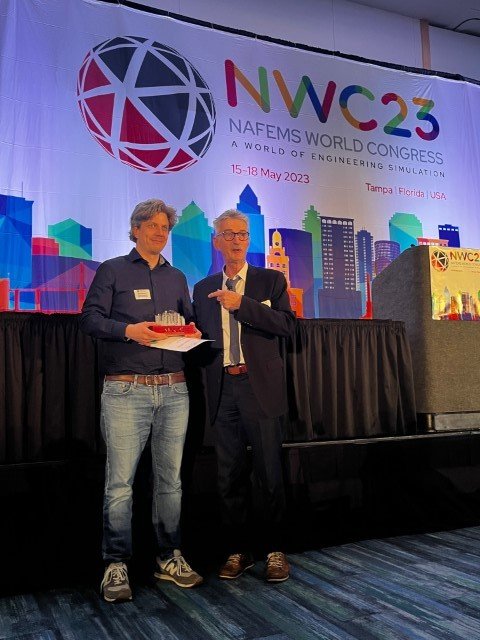

Innovative use of Simulation Technology

Decision Making and Visualization Tool for Automotive Vehicle Setup

Mariam Emara, Michael Balchanos, Burak Bagdatli, & Dimitri Mavris (Georgia Institute of Technology)

The authors here have developed a parametric decision-making environment that aids vehicle setup, focusing on the suspension system, using digital twin technology. The tool uses models of vehicle kinematic tests to calculate and visualise the results of different suspension setups, allowing for effective digital testing and tuning of vehicle options.

The decision-making platform, built in Python, allows users to select desired suspension parameters, while the backend uses surrogate models to predict the vehicle performance. An interactive user interface displays output plots and visualisation elements to provide insights about the performance of the chosen setup and allows comparison with a baseline configuration.

The authors demonstrated the tool with a use case of suspension tuning, highlighting its potential to quickly inform decisions without the need for expensive simulations or physical tests.

Sponsored by: